Paper Cushioning Systems

Alta Packaging offers top-of-the-line paper cushion packaging systems to protect your items against damage during handling, storing, and shipping. Using sustainable sources, our paper cushioning systems can safeguard your products effectively and successfully, which will improve your business’ bottom line. In addition, these systems are easy to operate and require minimal maintenance, preventing unnecessary downtimes during your operations.

Importance of Eco-Friendly Paper Cushioning Systems

- Paper packaging systems provide for environmental stewardship throughout your packaging operation.

- Our paper is produced from 100% recycled fibers and can easily be reused or recycled by a receiving customer, saving on natural resources.

- Since paper materials run through a machine convert to up to 80 times its original volume, less material is required to provide more protective packaging performance for a wide range of product applications.

- Paper systems represent a holistic design approach for cost-effective use of sustainable resources.

Single Ply Void Fill Paper Cushioning Systems:

Our paper cushioning system can dispense a single ply of packaging paper, which means the paper only has one layer. It’s ideal when cushioning is not a priority or when using dunnage bags to reduce shipping costs. This type of system is also commonly used for light and non-fragile items.

- For lightweight products and to prevent products from moving inside of a carton.

- Fast, lightweight and portable.

- Feed to length allows operators to dispense paper at varying lengths

Single or 2-Ply Cushioning Paper Systems:

The automated system can dispense single or 2-ply paper packaging material, so it’s perfect for light or medium-weight products. It’s also ideal for medium-sized and small businesses that ship multiple packages daily.

- Produce ultra- strong cushions for smaller shipping cartons.

- Fast, convenient packaging on demand.

- Automatic, semi-automatic or foot pedal operation.

- Converts paper up to 60 times its original volume.

Multi-Ply Cushioning Paper Systems:

Multi-ply paper cushion packaging systems can automatically dispense recyclable packaging paper for heavy, fragile, and bulky products. These systems are designed for high-volume operations and provide maximum protection for your items during shipping.

- Produce ultra- strong cushions for medium to large shipping cartons.

- Perfect for shipping heavy or valuable items.

- Automatic, semi-automatic or foot pedal operation.

- Converts paper up to 80 times its original volume.

- High speed paper conversion for fast moving operations.

- Adjustable height.

Applications of Our Paper Cushion Packaging Systems

Our paper cushioning machines can benefit facilities, warehouses, and e-commerce businesses. Since these are available in automatic, semi-automatic, and foot pedal operation, you can increase the output of your existing packaging processes. Moreover, these systems are versatile and can cater to various applications. Some examples include:

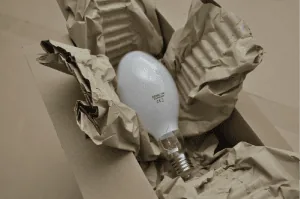

- Protecting breakable products such as glassware or electronics during shipping.

- Filling void spaces in packaging to prevent items from moving and tripping around inside the box.

- Creating custom-fit protective packaging for oddly shaped or delicate items.

Choose Expert Paper Packaging Systems for Your Void Fill Needs

Alta Packaging supports businesses that want to streamline their packaging operations while maintaining a sustainable approach. Our paper cushioning systems offer various options to meet your needs and protect your products during shipping. In addition, you can select a suitable configuration based on your packaging requirements!

If you’d like to know more about our paper packaging material systems, feel free to send us a message or give us a call today! Please speak to one of our representatives, and discover our other packaging systems here!

"*" indicates required fields