Products

Industrial Supplies for Facilities, Warehouses and Distribution Centers

Alta Packaging is a trusted source of industrial packaging solutions for numerous industries, primarily facilities, warehouses, and distribution centers. As experts in the field, we understand that each business has its unique packaging needs. Therefore, we offer a wide range of industrial packaging products to cater to diverse applications. Regardless of a facility’s operational complexity, we have the expertise and resources to provide quality packaging systems that meet the requirements of our clients.

We aim to deliver top-grade packaging products to improve our client’s bottom line while addressing their packaging issues. From automated packaging pouches to recycled paper filler systems, you can count on us to provide results that make sense in your unique daily processes while complying with different environmental regulations.

Complete Line of Packaging Products

Alta Packaging specializes in varying industrial packaging solutions made with quality and durability in mind. Our products are available at competitive prices, with most catalog items offered for next-day delivery. We prioritize efficiency and cost-effectiveness to help you keep your business running smoothly.

Our top-of-the-line packaging products include:

Liquid Foam Packaging

Liquid foam packaging is a special type of packaging solution that utilizes a special foam, which expands and molds into the shape of the enclosed product after activation. It’s triggered by the reaction of two or more liquid components and lets users package their products with only a minimum amount of material.

Benefits of opting for liquid foam packaging:

- Save floor space since they expand only when needed

- Flexible depending on the dimensions of the package

- Liquid foam can dramatically cut packaging costs

Cushioning Inflatables

An inflatable air cushion is an on-demand package filler, often in a plastic bag or fabric that can be inflated to provide cushioning. These are best used for demanding packaging projects that require faster turnarounds.

Benefits of inflatable air cushions:

- Quickly produce inflatable bubbles in 12″ and 24″ film widths

- Achieve speeds of up to 65 linear feet per minute

- Customizable cushioning output

Paper Cushioning Systems

Paper cushioning systems are also a type of package filler primarily used in paper void fill applications. However, it can also be used for cushioning, wrapping or blocking, and bracing products inside a box to better shield goods and fragile items.

Benefits of using paper cushioning:

- Made from 100% recycled fibers

- Reduce wastage since they’re more sustainable

- Cushioning lightweight products

Light Cushioning and Void Fill

The inflatable void-fill systems can produce air-filled cushions on demand. It can effectively reduce shipping and material costs while providing better protection for products in transit. It’s commonly set up on workstations or in-line applications since these systems are smaller and more compact than other inflatable void systems.

Benefits of inflatable void filling:

- Save warehouse space

- Lightweight protection

- Versatile packaging pouches

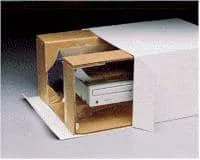

Suspension Packaging

For products that are highly sensitive to shock and vibrations, suspension packaging is the best solution. It involves suspending products within a container using specially constructed materials that absorb impact during transportation. These are primarily composed of a three-part system and two layers of polythene film that sandwich the product in the center of the carton.

Benefits of suspension packaging:

- Clean and professional-looking packages

- Cost-effective blocking and bracing protection

- Flexible film can accommodate products of any size and shape

Retention Packaging

Retention packaging is the ideal alternative to traditional packaging for an economical yet versatile packaging solution. It’s flat-packed as a die-cut piece, saving transportation costs and storage. It’s mainly used for flat objects. However, the elastomeric film can safely entrap products of any shape and size within the carton to prevent them from moving due to shipping, handling, and transportation cycles.

Benefits of retention packaging:

- Easy to assembly and fill without the need for additional adhesive

- Corrugated boxes provide an easy curbside recycling option

- The dual-layered structure offers excellent cushioning and protection for fragile items

Automated Cohesive Packaging

Automated cohesive packaging is the perfect solution for fast-paced environments requiring quick and efficient packaging systems. The materials used eliminate the need for hand-packing boxes, envelopes, mailers, or bags. For instance, the natural rubber-based materials in the poly mailer bag can adhere to themselves, encapsulating and securing the item inside the bag. The goal is to reduce labor while improving packaging productivity.

Benefits of automated cohesive packaging:

- Significantly lowers per-package costs

- Package 25 poly mailer bag packages per minute

- Packages of small items or e-commerce products

Automated Pouch Packaging

Automated pouch packaging systems automatically label, fill, and seal pre-made packaging pouches. It replaces manual hand loading, enhancing packaging speeds and lowering product handling errors, such as missing items or damaged goods. These are designed for flexible packaging applications, where various products can be packaged without changing the entire system.

Benefits of automated pouch packaging:

- Achieve speeds of up to 45 packaging pouches per minute

- Configurable to enhance operator productivity and ergonomics

- Packaging pouches of any length can be handled

Stretch Wrap Systems

Stretch wrappers are perfect for large items or boxes wrapped tightly in a film to secure onto a pallet. The automatic system handles the process and can encase pallets quickly without compromising the safety of goods. Our systems are reliable even in harsh working conditions.

Benefits of stretch wrap systems:

- Options include Semi-Automatic Turntable, Automatic Turntable, Semi-Automatic Rotary Arm, Orbital Stretch Wrap System, Semi-Auto Rotary Arm Legacy, and Automatic Rotary Arm stretch wrapping systems

- Ideal for high-speed wrapping of heavy or unstable loads

- Improve load containment and stability during transportation or storage

Strapping Systems

We offer a wide range of premium strapping tools and accessories, ergonomically designed for ease of use and high-velocity application. Our strapping tools are developed to meet the needs of any industry, from simple to heavy-duty applications. They’re small, light, and better balanced for easier operations.

Benefits of strapping tools:

- Operate with both polypropylene and polyester plastic strapping 3/8″ to 3/4″ wide up to .050 thick

- Pull up to 1200 pounds of tension

- Battery-operated and compact

Mail Spec Packaging

Years of knowledge in packaging improved our ability to identify the specifications required for military packaging. We have an extensive range of Mil-Spec packaging, such as desiccants, anti-static materials, static shielding materials, and more.

Benefits of Mail Spec packaging:

- Protect valuable products

- Shield items from weather conditions, harsh handling, moisture, etc.

- Guarantees no degradation or harm occurs during shipping

Improve Your Packaging Process with Cutting-Edge Packaging Systems

High levels of protection during transportation are essential for any business, and having high-performance packaging systems can enormously reduce the risk of damaged products or flawed items. Fortunately, our line of machines is made to meet the unique needs of various industries, from package filler solutions to automatic cohesive packaging with a simple poly mailer bag.

If you want to learn more about our products and services, don’t hesitate to contact us today. You may also call us at 8472152582, and our team will find a solution tailored to your operation’s needs!

"*" indicates required fields